VectorNav VN-210

The VN-210 is a small, high performance GNSS-Aided Inertial Navigation System (GNSS/INS) that combines 3-axis gyros, accelerometers and magnetometers, a Multi-band L1/L2/E1/E5b GNSS receiver, and advanced Kalman filtering algorithms to provide optimal estimates of position, velocity, and attitude. Each VN-210 and the embedded VN-210E feature a robust Kalman Filter (EKF) along with proprietary suite of high performance algorithms that run completely onboard the sensors. VectorNav’s industry leading INS provides high-accuracy position, velocity and attitude estimates along with compensated inertial measurements at rates between 400 and 800 Hz.

Key Benefits:

- VectorNav proprietary Extended Kalman Filter INS delivers coupled position, velocity, and a continuous attitude solution over the complete 360° range of operation

- VectorNav Processing Engine (VPE) for disturbance rejection, adaptive

filtering, dynamic filter tuning - Hard/Soft Iron Compensation (Real-time and Manual 2D & 3D)

- Individually calibrated for bias, scale factor, misalignment, and temperature over full operating range (-40°C to +85 °C)

- RTK Capable: Support for External RTCM 3 Inputs

- Raw GNSS Data: Exportable RINEX Data for PPK; Raw Psuedorange,

- Doppler and Carrier Phase outputs

- Support for external RTK GNSS receivers (NovAtel, Septentrio) &

- SAASM GPS receivers (ICD-GPS-153)

- Coning and sculling integrals (ΔV’s, Δθ’s)

- Data output format: ASCII (VectorNav), NMEA-0183, Binary (VectorNav), ARINC 4291

- IP 68 per IEC 60529 • Vibration & Shock (MIL-STD-810G)

- Temperature (DO-160G) • EMI & Radiation (MIL-STD-461G)

- Electrical (MIL-STD-1275E)

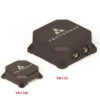

Ruggedized Packaging

The VN-210 features a precision milled, anodized aluminum enclosure designed to meet DO-160G standards. With dual I/O connectors the VN-210 offers maximum flexibility for interfacing with external GNSS receivers and IMUs. The VN-210 has an input voltage of 12 to 34 VDC power supply over a RS-422 interface.

Size: 56 x 56 x 31 mm

Power Consumption: < 2.5 watts

Weight: 155 g

Enclosed in a precision anodized aluminum enclosure, the VN-210 offers additional protection of the internal MEMs sensors and electronics. The use of precision CNC milled aluminum parts ensures that the axis alignment provided by the VectorNav factory calibration process is maintained during installation in its final configuration. Interfacing with the module is made through circular push-pull 10-pin connectors.